The following story provides an insider’s view of what it was like to work at Kenner during one of the company’s roughest transitional periods. The late 80’s and early 90’s saw Kenner change ownership several times. The employees were working in an environment that was full of uncertainty as the company changed hands, and toy lines and people were moved around. It wasn’t always fun and games at Kenner, and this employee saw it all. This is just one of the many stories to surface regarding the feelings many employees had during the late 80’s and early 90’s at Kenner.

This employee’s story also gives us a sneak peek into the toy development process at the time. It’s an interesting look into the steps it took to go from concept to production.

D. S.

1985-1999 Manufacturing

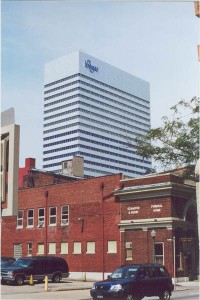

I worked at Kenner for almost 15 years, starting in 1985. When I started we were at the Kroger building in downtown Cincinnati. At that time we were owned by General Foods I think. They spun us off along with Parker Brothers to form Kenner-Parker toys. About 2 years later another company offered to purchase us. Kenner didn’t like the offer, and went in search of another buyer. Tonka toys bought us. About 2 years after that, Hasbro toys bought Tonka toys.

Every time there was a buy out, we had cut backs. When I started there in 1985, Kenner had the Kroger building, a manufacturing location in Oakley and a distribution center on Highland Ave. The distribution center was moved into the Oakley location as more and more of the manufacturing was moved off shore. Off shore was a term used for China, or for Mexico. The going rate for workers in Cincinnati at the time would be $8.00 per hr. while the off shore rates were $1.00 per hr. Large products were sent to Mexico to keep shipping cost down. When Hasbro bought us, they closed the distribution center at Oakley. When the lease came due at the Kroger building they got better terms to move to the new Gateway building where Kenner is located now.

The cut backs, downsizing layoffs, or whatever you call them were hard on both the ones out and the ones left. As one that was left you always wondered why your coworker was the one picked to be let go. Sometimes you could come up with a reason but other times it seemed that it was just a coin flip. Hasbro was not as friendly; they wanted to control how we did things and enforce their methods on us. We had procedures that were working, Kenner was making a profit and Hasbro insisted that we use their procedures. It was like they were more concerned with how we got to the end result than what the end result was. The cut backs never seemed to come at a good time, (not sure there is a good time) there were several years in a row that the cut backs would be announced the week after the Christmas party, we started calling the Christmas party the last supper.

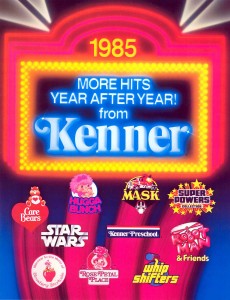

I worked on a lot of products over the years most of the time on boy’s toys which seems to be Kenner’s strong point. But I did spend several years on the girl’s team before it was sent to Rhode Island. I worked on Cindy a fashion doll that was to compete with Barbie, Littlest Pet Shop, and several other lines that never saw any large sales numbers. I was surprised to be still at Kenner after that move.

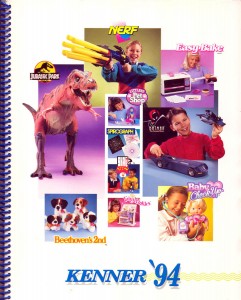

I spent about 4 years working on Batman toys, worked on Nerf, and did a little Star Wars. I also spent a lot of time on food toys and Play Doh. There were so many I enjoyed working on. Nerf was a favorite; my kids were the right age and they enjoyed playing with the toys I was working on. But I really had no favorite. Otherwise there were hundreds of misc. toys from lines that were only around for short runs and in some cases never even made it to production. I went for almost 2 years working on projects that never went into production. That was the thing with toys you never knew what was going to be the big hit.

We would start toys based on ideas that people felt would sell. At some point someone would come up with an idea for a toy or a line. The Designers would start making sketches, (this took several weeks) as the sketches started to take shape, models would be started to show play features (several more weeks). Marketing would make suggestions and do some research about package and sales information. Engineering would look at the items and a quick cost sheet would be done. This part could take any where from 2-3 weeks to 2-3 months depending on workload and time of year.

If Marketing liked the design and cost, then the project would be started. Engineering would start the toys design, and the Designers would finalize details on how the toy would look, and do color studies. In 10 to 16 weeks the final design would be done and we would head to tool start. 12 to 16 weeks later we would have first shots. Samples would be built and test changes made. 12 weeks later we should be at production start. In about 2-3 weeks we would have first ship. Toys arrive at the distribution center in about 4 weeks ready for shipment. From concept to on the shelf at Toys R Us was anywhere from 40 to 60 weeks depending on how fast we wanted the project and what problems came up.

At “tool start”, there would be a go/no-go decision, again just before “production start” there would be another go/no-go time. Once a no-go choice was made all work would stop and we would start on another idea. I have no real facts on these numbers but I felt that of 100 ideas sent in for us to work on we might work on 10, of those 10 only 1 or 2 would make it to production, and of every 100 toys that made it to production only 1 would be a real hit. A lot of ideas that we worked on were for whole lines. Kenner didn’t do many 1-item toys. They always wanted ideas that would become lines. Lines always had lots of toys at many price points.

This story was originally presented on KennerToys.com.

Did you previously work for the Kenner toy company?

We would love to hear your story!

Just click here to send us an email,

and you can help preserve the Kenner history.

thanks for sharing…i often wonder how was it like to work for The mask section. almost every boy had it.

My husband worked for Kenner toys in the 1960 I am wondering if the Company had a retirement plan could someone share this information